DAEBO Engineering & Construction efficiently manages quality, environment and safety policies.

-

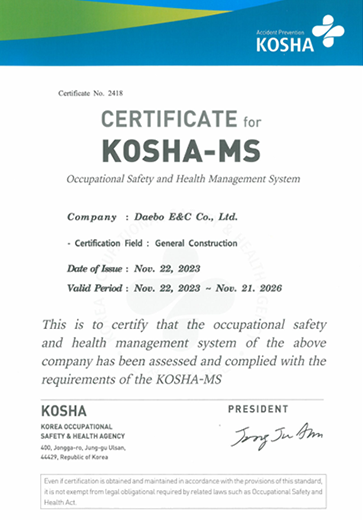

DAEBO Engineering & Construction has obtained international quality and environmental management system certifications (ISO9001 / 14001) and Occupational Health and Safety Assessment Series (OHSAS 18001) with KOSHA18001 (Korea Occupational Safety Health Agency). Since 2011 we have operated effective, integrated management of quality, environment, and safety/health policies.

Our quality policy

- First,

- Top quality realized by measurable objectives and regular assessment.

- Second,

- Maximized customer satisfaction by improved performance through continuous innovation.

01Top quality

02Environmentally-friendly construction

03Culture of voluntary safety control

Zero accident

Maximize cust–

omer satisfaction

through contin–

uous innovation

DAEBO Engineering & Construction

practices environmental and safety management.-

DAEBO Engineering & Construction practices environmental and safety management through organic cooperation among the CEO, project management division (including safety and environmental team and relevant business units), and a construction site. The environmental organization at the construction site is supervised by the site manager, who is the on-site environment-in-charge and promotes organic cooperation at the site.

The safety organization is composed of the site manager, who is the on-site safety/health-in-charge, safety manager who provides general instructions and advice, and safety supervisor who is in charge of managing/supervising safety and accident prevention.

- CEO

- Safety and Environmental Team

- Project Management Div.

- Project Div.

- Construction / Civil Engineering Team

- Site Manager

- Safety Manager

- Safety Supervisor

- Environment Supervisor

- Quality Supervisor

On-site environmental

management system

Depending on the results of the periodic monitoring,

Corrective action is taken immediately in case of nonconformity.-

When the construction site is prepared, design documents based on an environmental impact assessment and results of relevant discussions, are reviewed and analyzed in order to assess potential environmental impact and hazards caused by the project. Then, environmental management promotional plans for the site's environmental objectives, applicable to the site, are developed, and the on-site environment manager makes a checklist according to environmental inspection plans developed by the site manager. Later, regular monitoring is conducted to identify any non-conformance and to provide corrective measures.

Process of the on-site environment management

01Review of the

site and design

documents02Environmental

impact

assessment03Environmental

objectives04Environmental management

promotional plans05Monitoring and measurement

06Environmental inspection

On-site

safety control

system

DAEBO Engineering & Construction is actively utilizing

smart risk assessment system.-

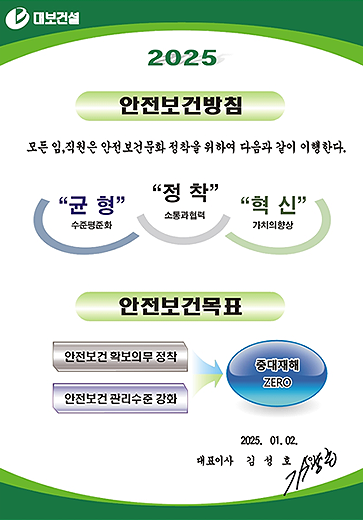

DAEBO Engineering & Construction has obtained KOSHA-MS/ISO45001 and promoted accident prevention activities systematically. In particular, KOSHA-MS, which we obtained in November 2017, for the first time as a mid-sized constructor, is a system for eliminating hazards in advance through

the cycle of Plan→Do→Check→Action.

On-site safety control process

Safety and health

management policyHazard assessment

Meeting for

communication-

Safety training

Safety activity

Safety

inspectionContinuous improvement

Maximize cust–

omer satisfaction

through contin–

uous innovation